In today’s resource-conscious world, repurposing and rebuilding old industrial equipment has become a practical and eco-friendly solution across many sectors. One standout example is the reconstruction of scrap transformers, which can be successfully refurbished and repurposed for new applications. By giving these powerful machines a second life, companies not only reduce waste but also save money and support sustainable practices.

The Lifecycle of a Transformer

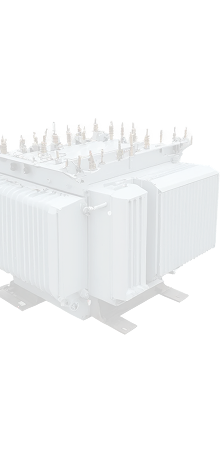

Transformers are vital components in electrical infrastructure, playing a key role in voltage regulation and power distribution. Over time, due to mechanical wear, environmental factors, or obsolescence, many transformers reach the end of their initial operational lifespan. However, that doesn’t mean they’re destined for the landfill. Instead, they can be expertly assessed, repaired, and upgraded for renewed functionality.

At JJ TRANSFORMERS, a leading transformer company, we specialize in acquiring old or non-functioning units and rebuilding them into reliable power solutions. Whether you’re looking for a transformer to buy or want to understand the potential of refurbished equipment, our team ensures each transformer meets or exceeds industry standards after restoration.

Key Steps in Rebuilding Scrap Transformers

1. Initial Inspection and Dismantling

The rebuilding process starts with a thorough inspection to determine the core condition of the transformer. Technicians dismantle the unit and assess the usability of key components such as the core, windings, bushings, and tank.

2. Core Reconditioning or Replacement

If the core is in salvageable condition, it’s cleaned and re-laminated. If not, it is replaced with new materials. This step is crucial to ensure efficient magnetic performance.

3. Rewinding Coils

Old windings are stripped away and replaced with new copper or aluminum windings, precisely tailored to match the transformer’s required voltage and capacity.

4. Tank Refurbishment

The tank is cleaned, sandblasted, and repainted. Gaskets and seals are replaced to prevent future leaks, ensuring a long and safe service life.

5. Testing and Certification

Before any rebuilt unit is released, it undergoes rigorous electrical and mechanical testing. At JJ TRANSFORMERS, every refurbished unit complies with strict quality assurance protocols as part of our transformer services.

Why Rebuild Scrap Transformers?

Cost Efficiency

Buying a rebuilt transformer is significantly more affordable than purchasing a brand-new unit. Customers looking to buy used transformers find great value in our competitively priced, high-performing refurbished models.

Environmental Benefits

Rebuilding reduces industrial waste and the demand for raw materials. This aligns with many companies’ sustainability goals and minimizes their environmental impact.

Fast Turnaround

Unlike ordering a new custom-built transformer that might take months to deliver, rebuilt transformers can be sourced and installed much more quickly—ideal for urgent replacements.

Applications for Rebuilt Transformers

Rebuilt units can serve in a wide range of sectors, from manufacturing plants and construction sites to temporary power setups and renewable energy projects. They’re especially useful for operations that need dependable, yet cost-effective equipment.

For those searching for “used transformers for sale near me”, JJ TRANSFORMERS maintains an updated inventory ready for immediate delivery.

Partner with JJ TRANSFORMERS for Quality and Reliability

Whether you’re looking to buy used transformers, need expert transformer services, or want to invest in a rebuilt top transformer, JJ TRANSFORMERS is your go-to partner. With years of hands-on experience and a commitment to engineering excellence, we help businesses across North America get the most out of their power systems—without the hefty price tag.