In industrial settings, every minute of downtime can translate into substantial financial loss. When transformers fail, operations can grind to a halt, causing delays, loss of productivity, and increased operational costs. One cost-effective solution to mitigate these issues is transformer rewinding—a process that restores damaged transformers to optimal functionality without the need for full replacement.

At JJ TRANSFORMERS, we specialize in delivering high-performance transformer services tailored to the needs of modern factories. Let’s explore how transformer rewinding helps reduce downtime and why it’s an essential part of industrial maintenance planning.

What is Transformer Rewinding?

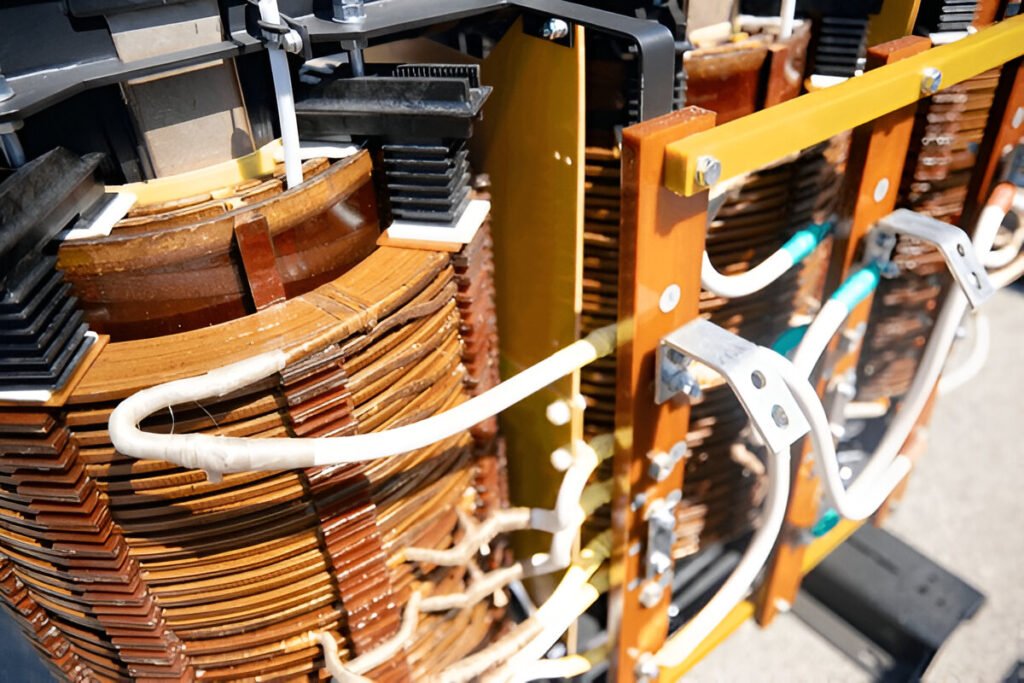

Transformer rewinding involves replacing or refurbishing the coil windings inside a transformer, which are often the first components to degrade due to electrical stress, overheating, or mechanical damage. Instead of purchasing a new transformer—an often time-consuming and costly process—rewinding restores the existing unit, extending its life and performance.

Benefits of Transformer Rewinding in Factory Operations

1. Minimized Downtime

One of the biggest advantages of transformer rewinding is speed. Acquiring a brand-new power transformer can take weeks, especially if it’s a custom or high-capacity unit. In contrast, rewinding can often be completed within days, allowing factories to resume operations quickly.

2. Cost Savings

Rewinding a transformer typically costs significantly less than replacing it with a new one. For budget-conscious operations, this solution offers a practical way to maintain productivity without incurring massive expenses. Whether you’re operating transformers in California or nationwide, reducing unnecessary equipment replacement is always a smart financial move.

3. Improved Efficiency and Performance

When done by professionals, transformer rewinding doesn’t just restore functionality—it can improve it. Modern insulation materials and advanced winding techniques can make an old transformer more efficient than when it was new. This is especially valuable in high-demand environments like factories where energy efficiency impacts profitability.

JJ TRANSFORMERS: Experts in Reducing Factory Downtime

At JJ TRANSFORMERS, we understand the critical role transformers play in manufacturing and industrial environments. Our transformer services include diagnostics, rewinding, upgrades, and full refurbishments to ensure uninterrupted operations.

Need to get rid of obsolete or broken equipment? We also sell used transformers and accept surplus transformers from industries looking to maximize asset value and reduce waste.

When to Consider Transformer Rewinding

If you’re facing inconsistent voltage output, overheating, or strange noises from your transformer, these could be signs that the winding is damaged or worn. Before investing in a replacement, consult a professional to determine if rewinding is a viable and more cost-effective option.

Even in non-industrial settings, like transformers for home or smaller commercial applications, rewinding can extend equipment life and improve electrical reliability.

Final Thoughts

Transformer rewinding is a smart, efficient, and cost-effective strategy to reduce downtime in factories. It allows for rapid restoration of critical power systems, lowers maintenance costs, and enhances the performance of existing equipment. By partnering with a reliable provider like JJ TRANSFORMERS, factory owners can keep their operations running smoothly while avoiding the costly pitfalls of extended outages.

Whether you’re managing heavy-duty power transformers or have surplus transformers to offload, we have the expertise and services you need.